PLA vs PETG vs ABS: Which Filament Should You Use?

Every 3D printing forum has this question posted at least once a week. Someone just got their first printer, they’ve got a spool of PLA that came with it, and now they’re wondering — should I try PETG? What about ABS? Which one is “better”?

The honest answer: none of them is universally better. Each one has a job it’s best at, and situations where it falls flat. I’ve printed thousands of hours with all three, and I pick my filament based on what the part actually needs to do — not based on internet hype.

Here’s the real breakdown.

PLA: The Easy One

PLA (Polylactic Acid) is where almost everyone starts, and for good reason. It’s derived from corn starch or sugarcane, prints at low temperatures, barely warps, smells faintly sweet, and produces consistently good results with minimal fiddling.

PLA Print Settings

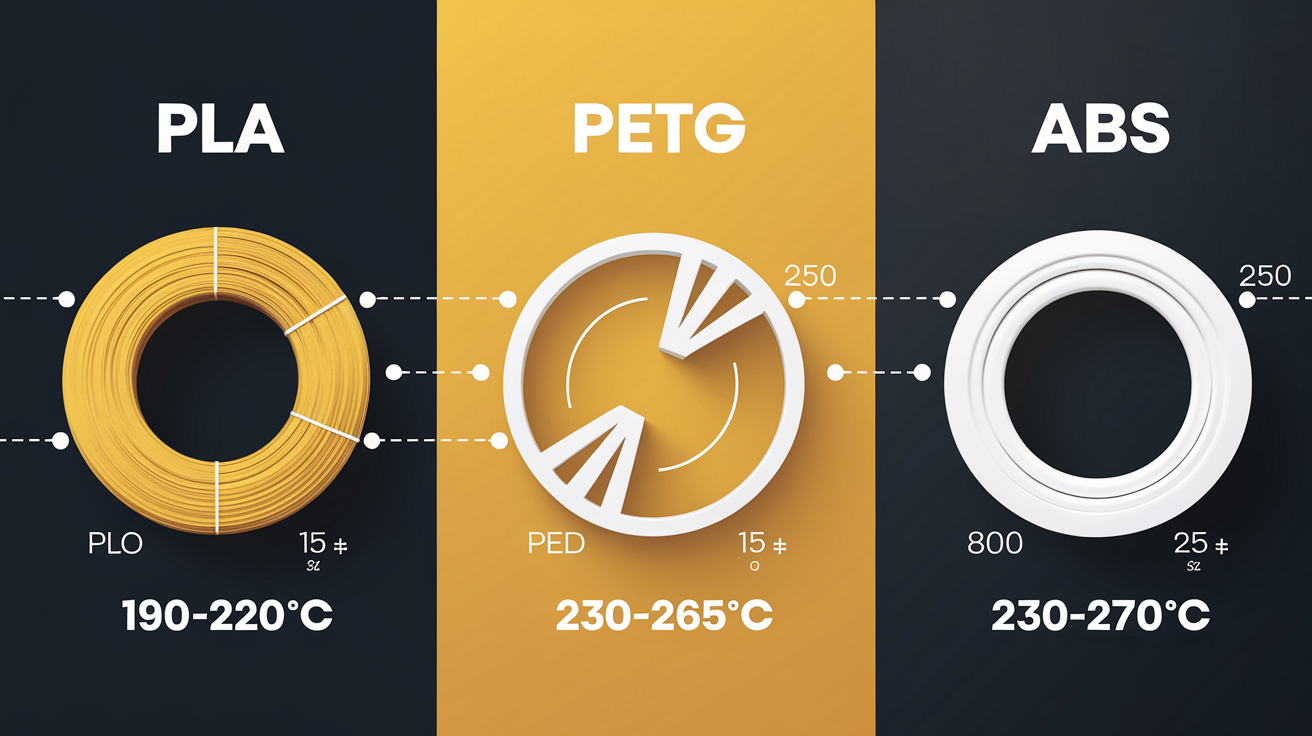

- Nozzle temperature: 190-215°C

- Bed temperature: 50-60°C (works fine without a heated bed too)

- Print speed: 40-80mm/s (can push to 150mm/s+ on machines like the Bambu Lab P1S)

- Cooling fan: 100% after the first layer

Where PLA Shines

Prototyping. When I need to check if a design fits, PLA is my go-to. It’s fast, cheap, and accurate. I can crank out three iterations of a bracket in an afternoon and test each one.

Display models and cosplay props. PLA holds fine detail beautifully and sands well with a bit of patience. The surface finish straight off the printer is usually better than PETG or ABS.

Low-stress functional parts. Cable clips, desk organizers, phone stands, shelf brackets that hold light items — PLA handles all of this without drama.

Where PLA Falls Apart (Literally)

Heat. PLA starts softening around 55-60°C. I left a PLA phone mount on my car dashboard one summer and came back to a melted blob. Anything that sits in direct sunlight, near electronics that generate heat, or in a car is a bad candidate for PLA.

Impact resistance. PLA is stiff but brittle. It snaps rather than flexes. Drop a PLA part on a hard floor and it’ll shatter. Compare that to PETG, which dents but holds together.

Outdoor use. UV exposure degrades PLA over time, and moisture absorption makes it brittle. Garden stakes, mailbox parts, outdoor enclosures — skip PLA for these.

PETG: The Middle Ground

PETG (Polyethylene Terephthalate Glycol-modified) is the compromise filament. Stronger than PLA, easier than ABS, and resistant to water and many chemicals. It’s the material I reach for when a part needs to actually survive real-world use.

PETG Print Settings

- Nozzle temperature: 220-245°C

- Bed temperature: 70-85°C

- Print speed: 40-60mm/s (it likes slower speeds)

- Cooling fan: 30-50% (too much cooling causes poor layer adhesion)

Where PETG Shines

Functional parts that take stress. Tool holders, jigs, mechanical brackets, drone frames — anything that needs to handle repeated loading without cracking. PETG flexes before it breaks, which makes it way more forgiving than PLA for mechanical applications.

Water-resistant applications. PETG is essentially the same family of plastic as water bottles. It barely absorbs water and works great for planters, water fittings, and bathroom accessories.

Semi-outdoor use. It handles UV exposure much better than PLA. I’ve had PETG parts outside for over a year with minimal degradation. It’s not bulletproof outdoors, but it’s leagues ahead of PLA.

PETG’s Annoying Quirks

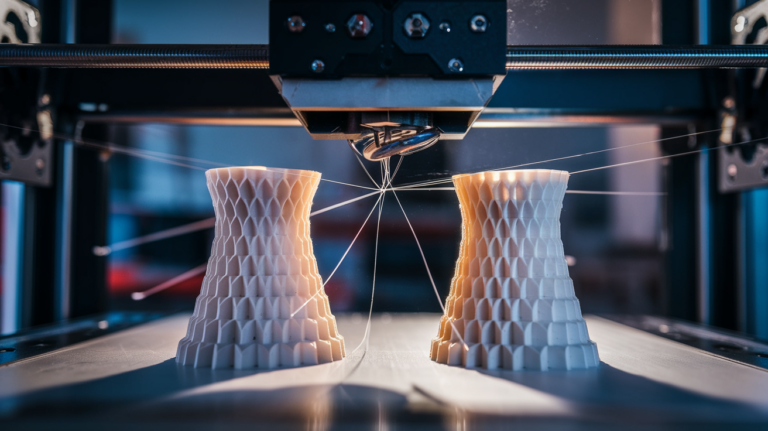

Stringing. Oh man, the stringing. PETG oozes like crazy. You’ll need to dial in your retraction settings carefully and accept that some post-processing might be needed. A quick pass with a heat gun cleans up the worst of it.

Bed adhesion — too much of it. PETG bonds to glass and PEI sheets so aggressively that it can rip chunks out of your build surface. I always apply a thin layer of glue stick on PEI before printing PETG. Sounds backwards, but the glue actually acts as a release agent.

Hygroscopic. PETG absorbs moisture from the air faster than PLA. If your PETG has been sitting open for a few weeks, you’ll hear it popping and sizzling during printing. Dry it before use.

ABS: The Old Guard

ABS (Acrylonitrile Butadiene Styrene) was the original FDM filament — it’s what the first MakerBots and RepRaps printed with. It’s tough, heat-resistant, and used in tons of commercial products (LEGO bricks, keyboard keycaps, car interior trim). But printing it at home requires more effort.

ABS Print Settings

- Nozzle temperature: 230-250°C

- Bed temperature: 90-110°C

- Print speed: 40-60mm/s

- Cooling fan: OFF or 10-20% max

- Enclosure: Strongly recommended

Where ABS Shines

Heat resistance. ABS handles temperatures up to about 100°C before it starts to soften. That makes it perfect for under-hood car parts, electronics housings near heat sources, and kitchen tools that might see hot water.

Post-processing. ABS dissolves in acetone, which means you can acetone-vapor-smooth parts to get a glossy, injection-molded look. You can also chemically weld broken ABS pieces back together. No other common filament offers this.

Toughness. ABS is both strong and impact-resistant. It doesn’t shatter like PLA — it bends and absorbs energy. For parts that take repeated impacts or mechanical stress, ABS is a solid choice.

Why ABS Is Frustrating

Warping. ABS warps aggressively. Without an enclosure, large prints lift off the bed, curl at the corners, and crack mid-print. You basically need a printer with an enclosed chamber, or at minimum a cardboard box over your machine. I’m not even joking — the cardboard box enclosure is a time-honored tradition in the 3D printing community.

Fumes. ABS produces styrene fumes during printing. You shouldn’t print ABS in a bedroom or poorly ventilated space. An enclosure with a carbon filter helps, but ideally you’d have the printer in a garage or workshop with good airflow.

Bed adhesion. ABS is notoriously picky about bed adhesion. ABS juice (ABS scraps dissolved in acetone, applied to the bed) or Magigoo work well, but it’s another step to deal with.

Head-to-Head Comparison

Strength and Durability

In my experience, the ranking goes:

- PETG — Best combination of tensile strength and flexibility. It bends before it breaks.

- ABS — Similar strength to PETG but better impact resistance. More ductile under sudden loads.

- PLA — Highest stiffness of the three, but brittle. Great for rigid parts that don’t see impacts.

Heat Resistance

Clear winner: ABS at ~100°C glass transition. PETG sits around 80°C. PLA starts going soft at 55-60°C.

If your part will be anywhere near heat, eliminate PLA immediately.

Ease of Printing

PLA wins by a mile. No enclosure needed, no fumes, low temperatures, forgiving settings. PETG is a close second — it needs a bit more temperature and careful fan settings, but it’s manageable on any heated-bed printer. ABS is the most demanding, requiring an enclosure and careful environmental control.

Chemical and Water Resistance

PETG and ABS are both good here. PLA is the worst — it absorbs water slowly and degrades over time. For any application involving liquids or chemical exposure, use PETG or ABS.

So Which One Should You Pick?

Here’s my quick decision tree:

Use PLA when:

- You’re prototyping and iterating quickly

- The part is decorative or display-only

- It’ll live indoors at room temperature

- You want the easiest, most reliable prints

Use PETG when:

- The part needs to be strong and somewhat flexible

- It might get wet or go outdoors

- You need food-safe-ish properties (PETG itself is food-safe, though 3D printing introduces layer lines where bacteria can grow)

- You want durability without dealing with ABS headaches

Use ABS when:

- Heat resistance above 80°C is required

- You want to acetone smooth for a professional finish

- The part takes repeated impacts

- You have an enclosure and proper ventilation

I keep all three on hand at all times. About 60% of what I print uses PLA, 30% PETG, and 10% ABS. Your ratio might differ depending on what you make, but that split has served me well.

A Word on Newer Alternatives

The filament world has evolved. ASA is basically UV-stable ABS — great for outdoor parts without the UV degradation. PLA+ variants from brands like eSUN and Polymaker offer improved impact resistance over standard PLA. And PETG-CF (carbon fiber reinforced) adds stiffness without the warping headaches of ABS.

Don’t feel locked into just these three. But PLA, PETG, and ABS are the foundation. Master them first, and branching out to specialty filaments becomes much easier.